Processus de conception des installations de bus de terrain

L'infrastructure de bus de terrain constitue l'épine dorsale d'un système d'automatisation. Des règles de conception s'appliquent conformément à toute installation électrique. Les critères de conception suivants sont importants pour garantir une fiabilité élevée et un bon rapport coût/efficacité :

- Topologie et composants

- Fonctions et disponibilité : options incluant la redondance ou la protection contre les courts-circuits, les surtensions ou l'humidité

- Bus de terrain en zone à risque d'explosion : modes de protection contre l'ignition classiques pour les installations de bus de terrain en zones et divisons

Topologie et composants : une conception et une manutention simplifiées

Un segment est un circuit simple doté d'une alimentation, d'une boîte de jonction pour bus de terrain et d'instruments. Il permet de raccorder plusieurs instruments à un système de commande. La conception topologique détermine l'emplacement physique et la connexion des alimentations, des boîtes de jonction pour bus de terrain et des instruments.

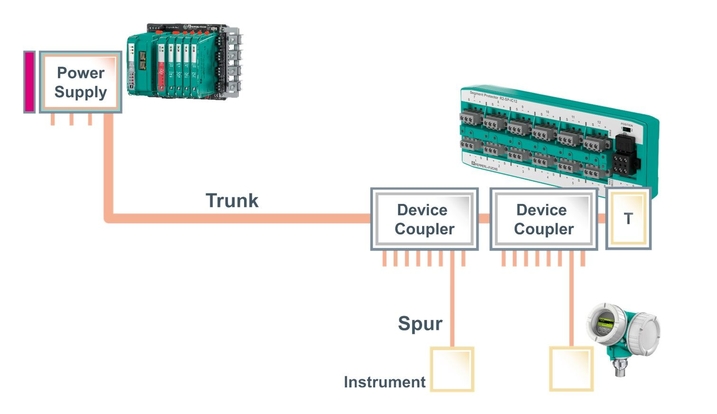

La topologie typique d'un segment comprend un tronc et des branches ainsi qu'une ligne principale ou un câble maître (le tronc). Le tronc connecte les alimentations et interfaces de communication situées en salle de commande aux équipements sur site. Une ou plusieurs boîtes de jonction pour bus de terrain, installées à un emplacement facile d'accès, permettent la connexion des appareils de terrain. Le câble de raccordement, d'une longueur maximale de 120 m, est qualifié de « branche », car il est généralement beaucoup plus court que le tronc. Cette topologie est adaptée à la quasi-totalité des usines.

Présentant de nombreuses similitudes avec les topologies connues, avec des câbles de tronc multibrin reliés à une boîte de jonction pour bus de terrain installée sur site, la topologie dite du tronc et des branches est facile à comprendre, à concevoir et à entretenir.

La topologie dite du tronc et des branches garantit une conception simplifiée. Chaque appareil est connecté séparément.

Il est également fait référence à la boîte de jonction pour bus de terrain en tant que « coupleur ». Si nécessaire, la protection contre l'ignition peut être renforcée à l'aide d'un choix d'alimentations et de coupleurs. Des solutions économiques peuvent ainsi être mises en place pour tout type de zone à risque d'explosion.

Téléchargez et installez l'outil logiciel gratuit pour concevoir et disposer vos segments de bus de terrain, mais aussi identifier la longueur de câble adaptée aux appareils que vous utilisez. Vous pouvez choisir les instruments de votre fabricant préféré au sein de bibliothèques d'appareils. L'installation de bus de terrain devient un jeu d'enfant …

Fonctions et disponibilité

Les coupleurs modernes fournissent une protection fiable dans des scénarios de travail classiques, comme l'échange d'appareils, le rebondissement de contact, l'humidité, les surtensions, etc. Pour découvrir ces fonctions en détail, cliquez ici …

FieldConnex simplifie la conception et la mise en œuvre d'installations de bus de terrain pour les usines de traitement de tous les secteurs, avec différents choix et différentes options pour garantir une protection contre les conditions de l'environnement et une disponibilité adaptées.

Pour découvrir tous les composants de bus de terrain à utiliser en zone non dangereuse et identifier les composants adaptés à votre usine, cliquez ici …

Bus de terrain en zone à risque d'explosion

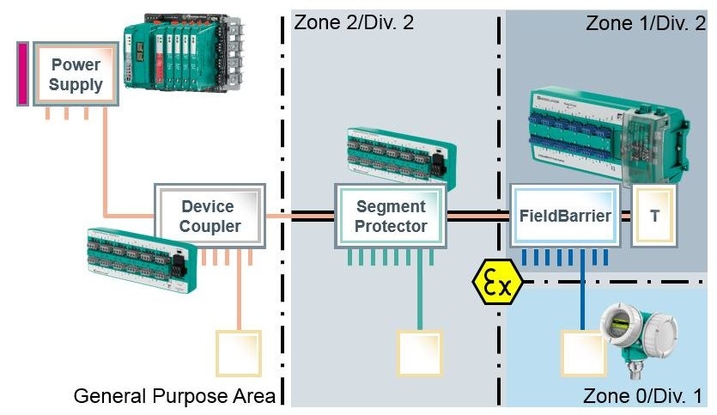

L'utilisation d'un bus de terrain en zone à risque d'explosion nécessite une infrastructure protégée contre l'ignition. Vous trouverez ci-dessous la topologie associée aux zones à risque d'explosion : Pour consulter des informations détaillées au sujet des modes de protection contre l'ignition, cliquez ici …

Topologie identique intégrant un tronc et des branches pour toute zone à risque d'explosion. La sélection des composants et des modes d'installation appropriés garantit la protection contre l'ignition.

- Demandez à un Expert

- Demande pour une référence équivalente

- Suivi de votre commande en cours

- Nouveautés

- Service Level Agreements for ecom instruments

- Où commander

- Sélection de documentations

- Technologies

- Solutions systèmes de contrôle

- Recherche de documents techniques, catalogues ou brochures

- Articles de presse

- Salons

+41 32 374 76 76

+41 32 374 76 76